Wind turbines rise into the sky on enormous feet. To ensure these giants can reliably generate electricity for many years to come, the iron processing industry must manufacture their massive components in a stable, resource-saving and yet cost-effective way. However, material inclusions such as dross are often unavoidable while casting. Fraunhofer researchers are currently working to detect and analyze such material defects.

Wind turbines should be environmentally friendly, highly efficient, cost-effective, and able to function reliably for at least 20 years. However, as turbines become increasingly powerful, the demands on the components used are growing, and so is the risk of material fatigue. Material defects such as inclusions from slag, known as dross, are considered undesirable because they greatly reduce the load-bearing capacity of cast iron components with spheroidal graphite. This special kind of cast iron is also used to make a wind turbine’s mainframe and rotor hubs. Manufacturing such components is difficult due to the build-up of dross that often occurs despite tricks in casting techniques.

Wind turbines rise into the sky on enormous feet. To ensure these giants can reliably generate electricity for many years to come, the iron processing industry must manufacture their massive components in a stable, resource-saving and yet cost-effective way. However, material inclusions such as dross are often unavoidable while casting. Fraunhofer researchers are currently working to detect and analyze such material defects.

Wind turbines should be environmentally friendly, highly efficient, cost-effective, and able to function reliably for at least 20 years. However, as turbines become increasingly powerful, the demands on the components used are growing, and so is the risk of material fatigue. Material defects such as inclusions from slag, known as dross, are considered undesirable because they greatly reduce the load-bearing capacity of cast iron components with spheroidal graphite. This special kind of cast iron is also used to make a wind turbine’s mainframe and rotor hubs. Manufacturing such components is difficult due to the build-up of dross that often occurs despite tricks in casting techniques.

That is why foundries make sure they liberally remove all the dross and release only dross-free products for use. Since defects of this kind are usually found on the surface of the cast part or a few centimeters below the casting skin, the raw cast part is grinded laboriously by hand. “Compared to other material defects, such as cavities in the component, there is as yet no way of reliably dealing with dross,” says Dr. Christoph Bleicher from the Fraunhofer Institute for Structural Durability and System Reliability LBF in Darmstadt. Since the beginning of 2015, he has been the consortium leader of the “unverDROSSen” project, which aims to move away from the customary requirements for dross-free products and thus dispense with the time-consuming post-production work.

Continue reading at Fraunhofer-Gesellschaft

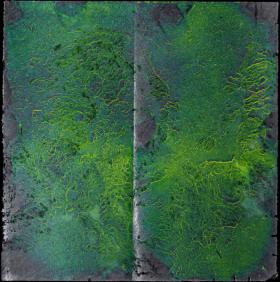

Photo: Dross in thick-walled cast iron with spheroidal graphite: casting surface after the fluorescent magnetic powder test. Credit: Fraunhofer LBF