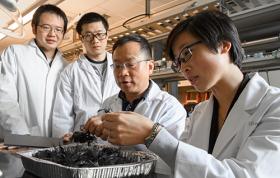

A WSU research team for the first time has developed a promising way to recycle the popular carbon fiber plastics that are used in everything from modern airplanes and sporting goods to the wind energy industry.

The work, reported in Polymer Degradation and Stability, provides an efficient way to re-use the expensive carbon fiber and other materials that make up the composites.

A WSU research team for the first time has developed a promising way to recycle the popular carbon fiber plastics that are used in everything from modern airplanes and sporting goods to the wind energy industry.

The work, reported in Polymer Degradation and Stability, provides an efficient way to re-use the expensive carbon fiber and other materials that make up the composites.

Planes, windmills, many products

Carbon fiber reinforced plastics are increasingly popular in many industries, particularly aviation, because they are light and strong. They are, however, very difficult to break down or recycle, and disposing of them has become of increasing concern. While thermoplastics, the type of plastic used in milk bottles, can be melted and easily re-used, most composites used in planes are thermosets. These types of plastics are cured and can’t easily be undone and returned to their original materials.

Caustic chemicals eliminated

To recycle them, researchers mostly have tried grinding them down mechanically or breaking them down with very high temperatures or harsh chemicals to recover the expensive carbon fiber. Oftentimes, however, the carbon fiber is damaged in the process. The caustic chemicals used are hazardous and difficult to dispose of. They also destroy the matrix resin materials in the composites, creating a messy mixture of chemicals and an additional waste problem.

Continue reading at Washington State University

Image via Washington State University